This website uses cookies

We use cookies to personalize and enhance your experience on our site. By using our site, you agree to our use of cookies.

In 2018, the corporate test lab of Sunway was nationally recognized as the "5G RF System and LCP Engineering Technology Research Center of Guangdong Province", by the provincial Department of Science and Technology. Its scope includes the entire Greater Bay Area of the high-tech region with center in Shenzhen.

Sunway's 5G mm-wave lab carries out 5G mm-wave antenna, 5G RF transmission material and high frequency electromagnetic simulation research. Within the same downtown location in the high-tech center of Shenzhen, multiple RF and reliability related measurement equipment combine to serve as a one-stop R&D facility lab to develop tomorrow's connectivity solutions.

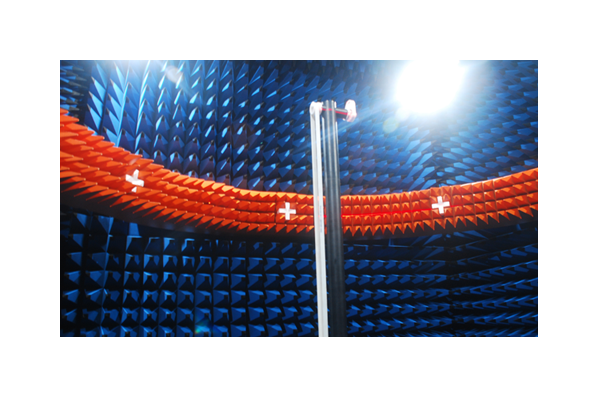

Since RF technology is at the core of Sunway, our test laboratories in all our design locations feature all required equipment for reliable and consistent RF measurements. For everyday engineering work, we have numerous network analyzers, spectrum analyzers, signal generators, communication tester and other equipment for circuit measurements. For antenna radiation patterns and antenna efficiency measurements, passive, active and OTA, we rely on several anechoic chambers from different well-known international brands, like Satimo, Dart, etc. In addition, we often test at system level for cellular conformance of GSM, WCDMA, LTE, 5G, NFC etc. In terms of compliance, we also take regular SAR measurements using the internationally recognized DASY system. Finally, we can also measure dielectric and magnetic material properties.

RF performance also includes the EMC (EMI & EMS) integrity of the end-user devices, which is something that we also have the ability to do, again accredited by CNAS and CTIA.

We ensure acoustic performance in our acoustic test chambers, also available in our design locations. We use globally recognized test systems, for example from B&K and Klippel, to ensure compliance to standards.

Mechanical properties like dimensions, hardness, etc are – similarly to many other equipment – available in all our design locations. These are used during the entire design process to ensure performance to specification. Environmental tests are also carried out in-house like temperature shock, humidity, RoHS compliance etc.

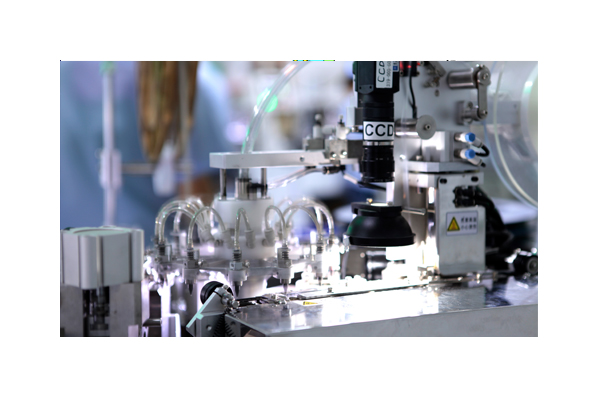

As part of our meticulous quality compliance process, we design in-process testing into our production line designs. Drawing upon our vast knowledge of design testing, as well as automation engineering, these production line tests take advantage of equipment relevant for the purpose of accuracy and speed.