This website uses cookies

We use cookies to personalize and enhance your experience on our site. By using our site, you agree to our use of cookies.

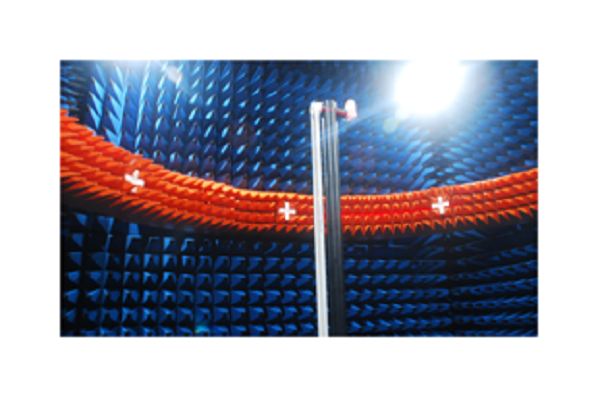

Sunway invests continuously in order to stay at the forefront of technologies, to ensure that we are the global leading provider of RF one-stop solutions. Key focus areas include antenna designs for current and future systems, like 5G, MIMO, RF Front-ends as well as new dielectric and magnetic materials and solutions in the various emerging IoT technologies. Our corporate Central Research Institute with activities in Shenzhen, China and Stockholm, Sweden is a driving force for these advancements. Naturally, Sunway also makes major investments in IPR and holds an impressive international patent portfolio within selected technology areas.

Sunway Communication is a company with a strong and solid base in R&D across multiple technology domains. At the core is our in-depth understanding of both theoretical and applied RF (Radio Frequency) Technologies. For a perfected RF solution we carry out computer simulations, something also done for mechanical optimizations. We also recognize the need for reliable mechanical solutions and the selection of adequate manufacturing processes. An upfront Design For Manufacturing analysis and Design for Cost approach is frequently carried out. Most of our customer projects are customized to specific needs and our blue-chip customer base relies on our ability to meet their most stringent requirements.

In RF, we bolster a wide range of components, modules and solutions to ensure total system performance optimization. These include antennas, RF Front-end modules such as switches, tuners and multiplexers, as well as RF optimized contact springs, connectors, cables, and LCP flexible transmission lines in the form of microstrips and striplines. The recent adoption of wireless charging for various devices has meant that we are now a major supplier of WPT (Wireless Power Transfer) modules, NFC modules and combinations thereof. Furthermore, 5G sets new requirements on high-performance materials and designs, both in the sub-6 GHz domain as well as at mm-wave frequencies. To achieve the highest performance levels, we perform several computer simulations as part of our design process. If your device requires wireless connectivity, you can count on Sunway to have the right solution. In many cases, we also integrate multiple components into high-performance miniaturized modules, for example antennas integrated onto a speaker box.

A high degree of vertical integration is one of the ways, in which we strive to leverage our technological advantages. Thanks to in-house manufacturing capabilities in key areas like molding, plating, punching, LDS (Laser Direct Structuring), MIM/CIM (Metal/Ceramic Injection Molding), precision assembly etc, we ensure that we have a close link between our design and manufacturing. This is essential in order to provide a fast process to market launch while meeting the most strict quality and cost requirements.

Our Sunway automation team includes over 200 experienced structural engineers, electronic control engineers and software automation engineers. It can design fully automatic production lines for mass production of parts for customers in consumer electronics, communication infrastructure, automotive, and more. At present, it has a huge pool of fully automatic laser welding lines, a large number of laser engraving lines and a significant amount of automatic flexible box assembly lines, including automatic visual inspection machines, automatic coiling machines, and a big amount of filming/labeling equipment, all used since long in mass production. Sunway also has the capability of precise 2D/3D size inspection and vision-guided dispensing, solder paste dispensing, soldering, etc. At the same time, company also cooperated with EPSON / ABB and used the robots to replace manual operation.